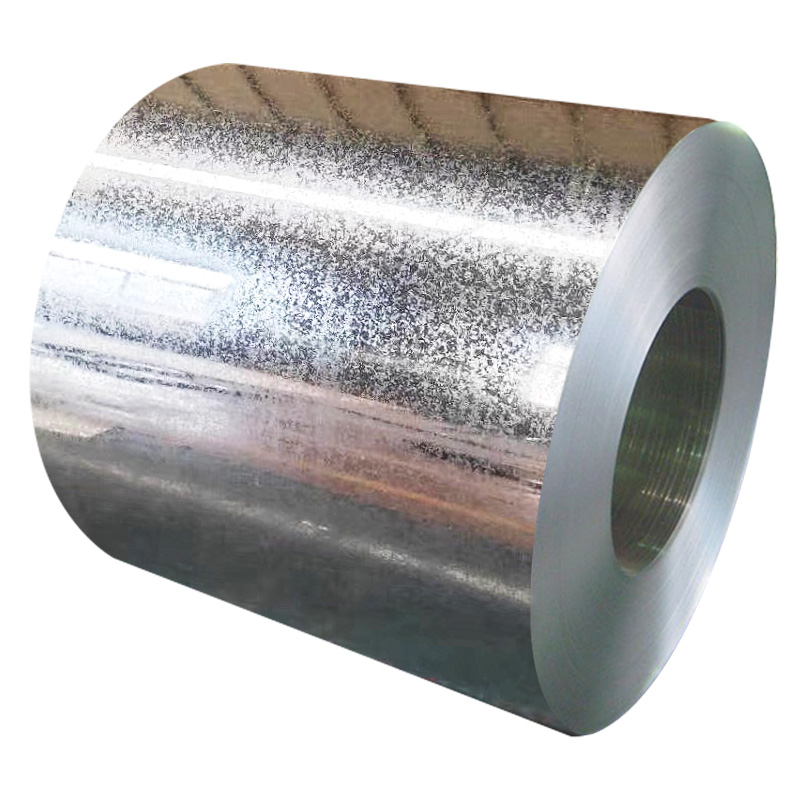

Galvanized Strip Production Process

1. Pickling and decontamination of the entire roll of strip steel to achieve a bright and clean surface.

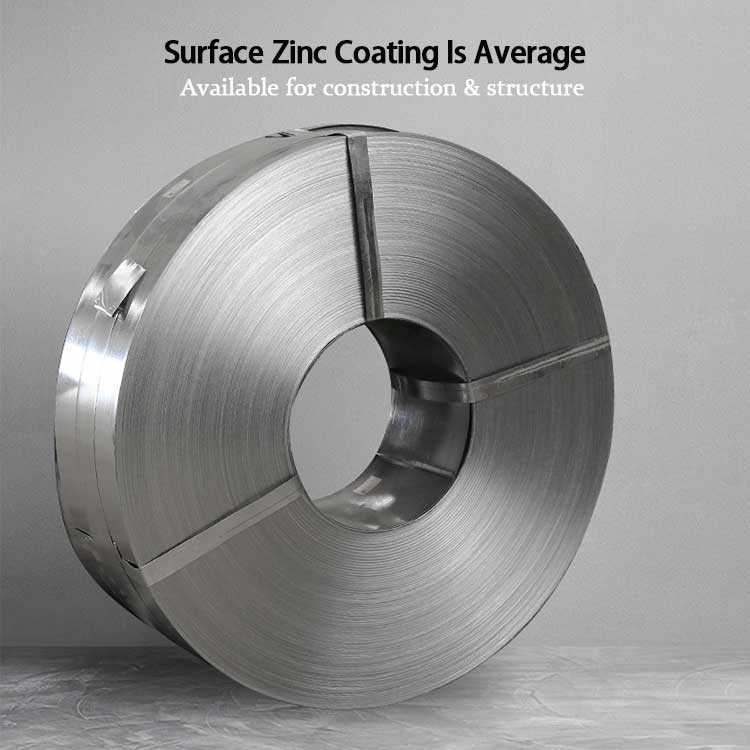

2. Hot-dip galvanizing: After pickling, it is cleaned in the tank of ammonium chloride or zinc chloride aqueous solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the continuous annealing furnace and then into the galvanizing tank for galvanizing.

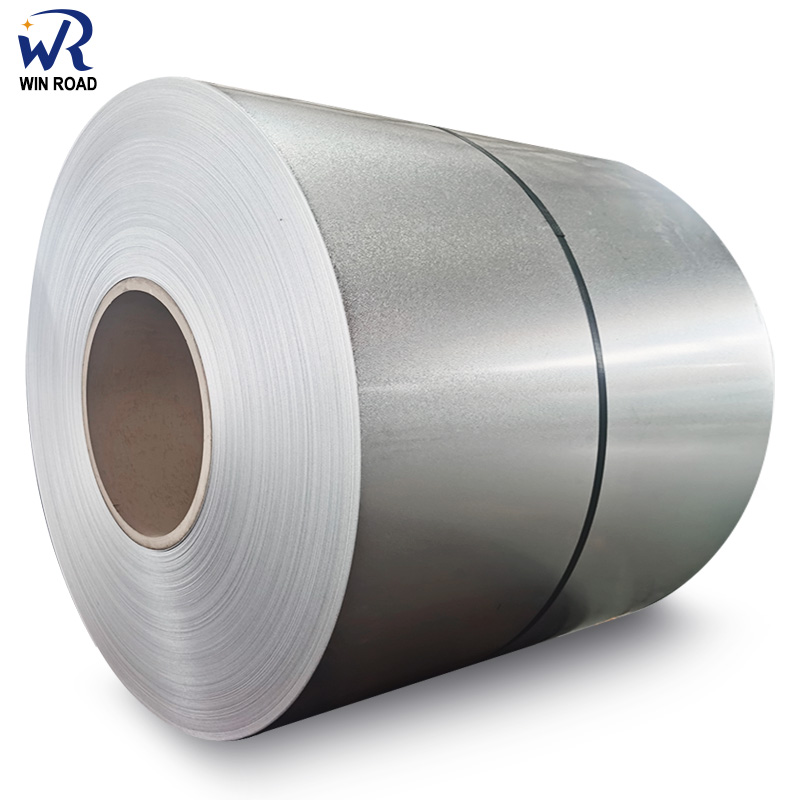

3. The strip is galvanized and put into storage, and the galvanized layer can be customized according to customer needs.

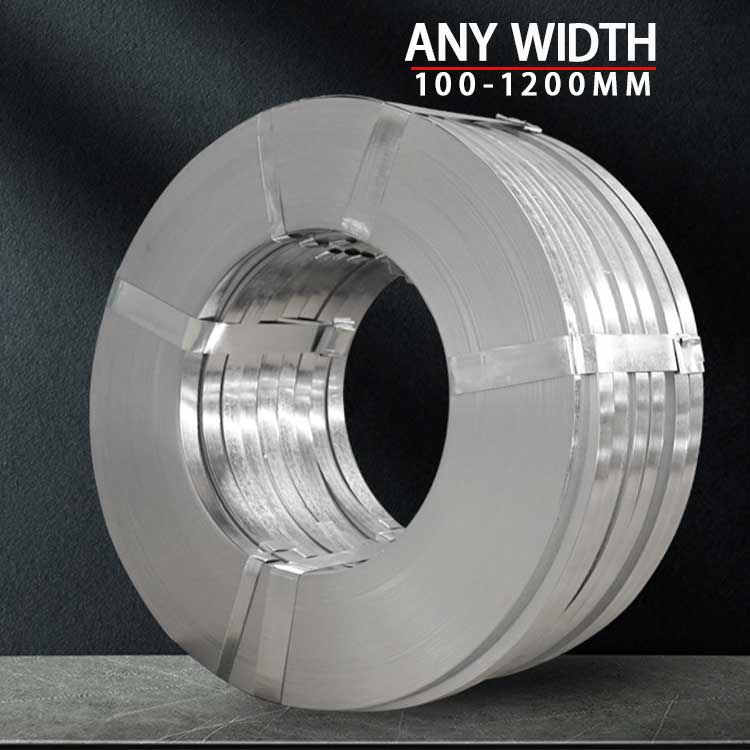

4. If there is a requirement for the width, the galvanized steel coil can be processed into strips. Generally, the thickness of the toxicity file is 0.12-2mm.

Galvanized steel strip specification can be customized according to customer’s requirement.

| Thickness | 0.12mm-3mm ; 11gauge-36gauge |

| Width | 50mm-500mm; |

| Standard | JIS G3302, EN10142, EN 10143, GB/T2618-1998, ASTM653, AS NZS 1397 |

| Material grade | SGCC, DX51D, G550, SPGC, ect. |

| Zinc coating | Z30-Z275g/㎡ |

| Surface treatment | Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print |

| Spangle | Small/ Regular/ Big/ Non-Spangle |

| Coil weight | 0.5-1 tons, one package is usually 3-5tons |

| Coil inner diameter | 508/610mm |

| Hardness | Soft hard (HRB60),medium hard (HRB60-85), full hard (HRB85-95) |

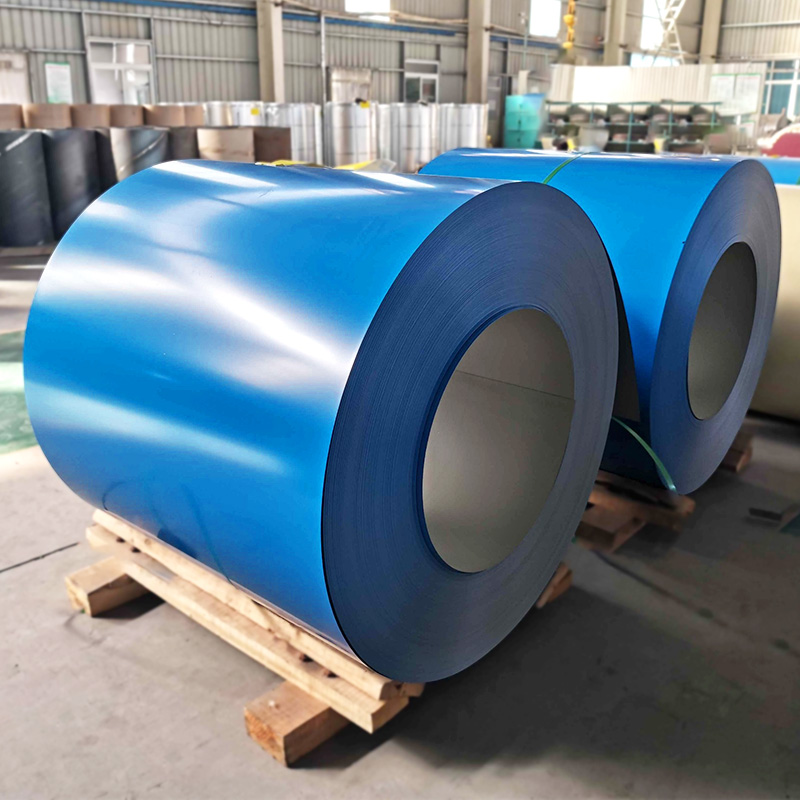

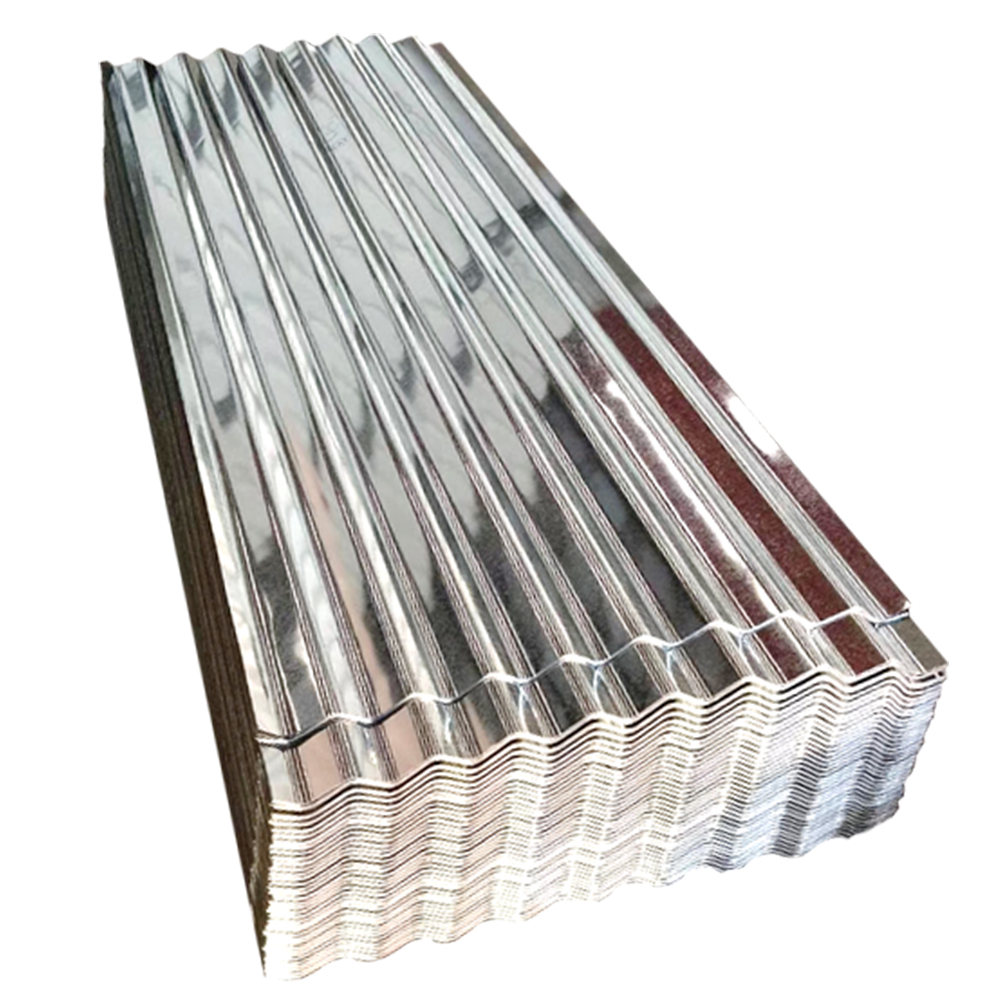

Galvanized steel coil/strips are widely used for construction, building, roof sheets, automobiles, agriculture,home appliances,vanitation pipe and commercial industries.

The galvanized steel strip base material can be divided into cold-rolled steel and hot-rolled steel. The thicness of galvanized strip with cold rolled steel is 0.12-2mm, while the thickness of galvanized strip with hot-rolled steel material is 2-5mm. The steel grade for cold rolled galvanized steel strips are G550, DX51D+Z, S350,S550, Q195, Q235, SGCC. The strip is generally slit from galvanized steel coils which width from 600-1500mm, so that any strip width is available.