-

0.42 x 103 g550 az150 aluzinc steel strip / galvalume steel strip

The coating structure of the galvalume steel strip is Zn-Al alloy, and the coating composition is 55% Al, 43.3% Zn, and 1.6% Si. Because of its excellent corrosion resistance, this kind of steel is widely used all over the world.

The development of aluzinc steel. In terms of supply and demand, after years of adjustments and market competition, China’s galvalume steel coil industry has gradually stabilized. The market supply and demand relationship is relatively balanced. The production and sales rate is above 90% every year, and a considerable amount of products are exported every year.

-

G550 az150 0.75mm Galvalume Steel Strip For Building Structure Frame

The coating structure of the galvalume steel strip is Zn-Al alloy, and the coating composition is 55% Al, 43.3% Zn, and 1.6% Si. Because of its excellent corrosion resistance, this kind of steel is widely used all over the world.

The development of aluzinc steel. In terms of supply and demand, after years of adjustments and market competition, China’s galvalume steel coil industry has gradually stabilized. The market supply and demand relationship is relatively balanced. The production and sales rate is above 90% every year, and a considerable amount of products are exported every year.

-

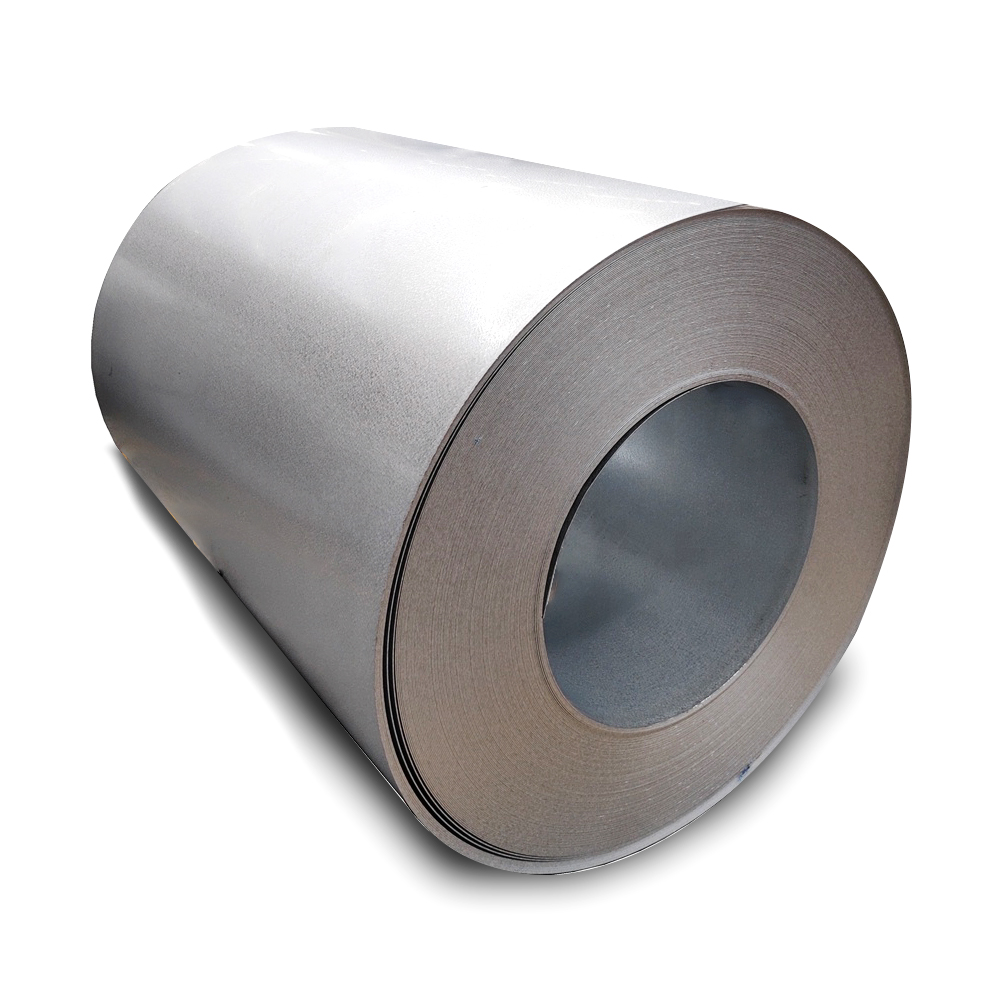

China Factory Direct Supply Aluzinc Galvalume Steel Coil AZ150

Galvalume Steel Coil also named Aluzinc Steel Coil /Zinc-alum Steel Coil. The base material is non-alloy low carbon cold rolled steel coil. The surface composition is 55% aluminium, 43.4% and 1.6% silicon cured at 600℃.Galvalume has a gorgeous silver-white surface.

With the development of various industries in the national economy, the market demand for galvanized products is increasing due to their excellent performance, and the market scale of the galvanized industry is also increasing. It is expected that the market will continue to grow in the future, until 2025. It will reach 147.761 billion yuan in the year.

-

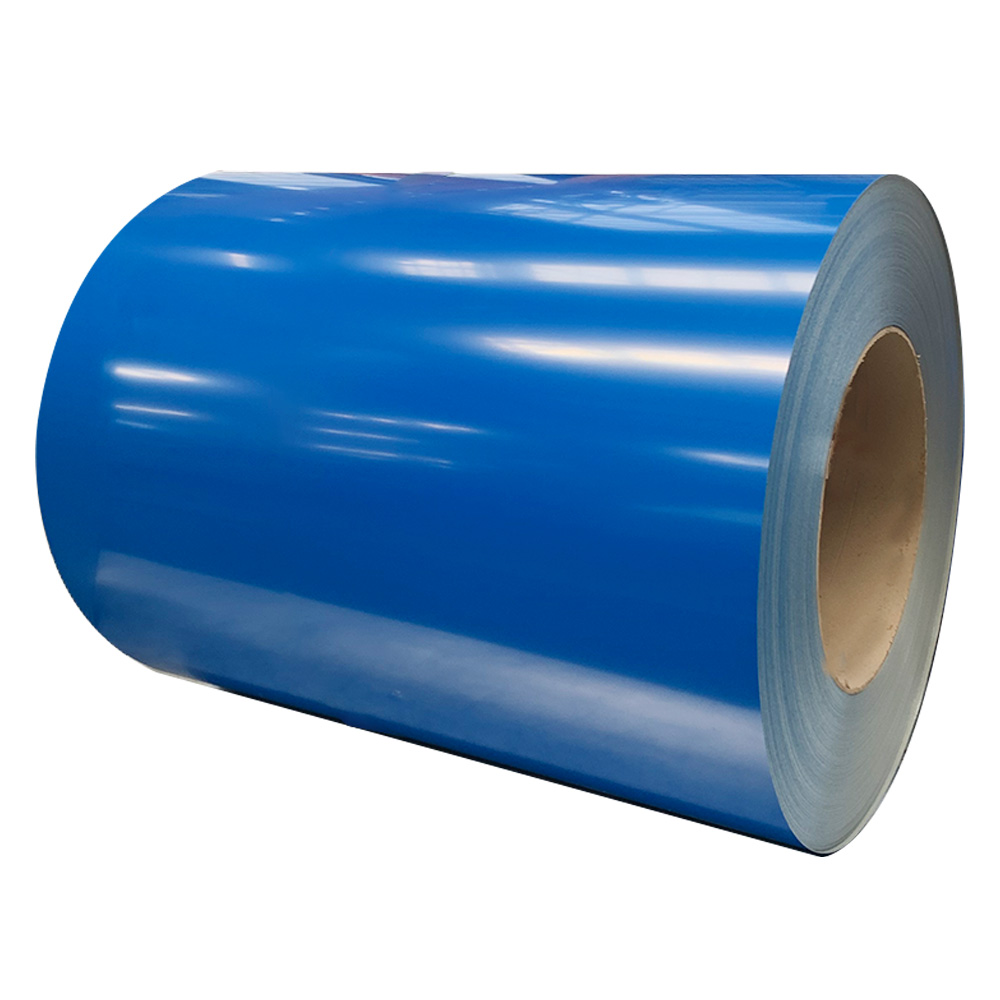

Grass Green RAL6010 Color Coated Steel Coil For Roofing, Building, Steel Structure

PPGI is an acronym for prepainted galvanized steel, it use galvanized as substrate. After surface pretreatment(chemical degreasing and chemical conversion treatment), the surface coated with a layer or several layers of coating, through baking and curing, then become the PPGI.

The paint film that we can do 10-30microns. The higher the paint film, the longer the service life of the color.

The painting material are PE, SMP, HDP, PVDF, ects.

-

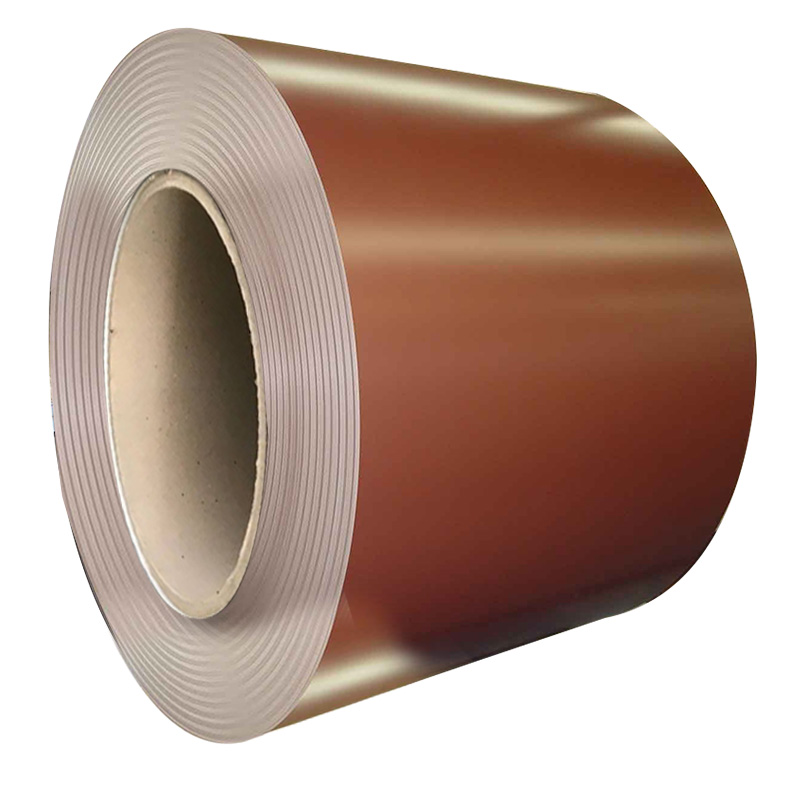

PPGI/PPGL Prepainted Steel Coil DX51D, SGCC, G550 Brown Color RAL8017, RAL8014, RAL8011

PPGI is an acronym for prepainted galvanized steel, it use galvanized as substrate. After surface pretreatment(chemical degreasing and chemical conversion treatment), the surface coated with a layer or several layers of coating, through baking and curing.

PPGL is prepainted galvalume steel coil. Base material is galvanized/aluzinc coil.

The paint film that we can do 10-30microns. The higher the paint film, the longer the service life of the color.

The painting material are PE, SMP, HDP, PVDF, ects.

-

Ppgl Steel Coils AZ150 For Roller Door Manufacturing 0.2mm 0.3mm

PPGL is an acronym for prepainted galvalume steel, it use galvalume as substrate. After surface pretreatment(chemical degreasing and chemical conversion treatment), the surface coated with a layer or several layers of coating, through baking and curing, then become the PPGL.

The paint film that we can do 10-30microns. The higher the paint film, the longer the service life of the color.

The painting material are PE, SMP, HDP, PVDF, ects.

-

High anti-corrosion al-mg-zn alloy steel coil /mg-al-zn coating, zinc aluminum magnesium coil

Zinc-Aluminum-Magnesium steel coil ( zn-mg-al plate) is a new type of high-corrosion-resistant coated steel plate. Its zinc-plated layer is mainly composed of zinc, which is composed of zinc plus 11% aluminum, 3% magnesium and a trace amount of silicon. The thickness range of the current steel plate can be produced is 0.13mm—6.00mm, and the production width range is: 580mm—1524mm.

-

zn-al-mg steel 、 aluminum zinc magnesium steel coils

Zinc-Aluminum-Magnesium steel coil ( zn-mg-al plate) is a new type of high-corrosion-resistant coated steel plate. Its zinc-plated layer is mainly composed of zinc, which is composed of zinc plus 11% aluminum, 3% magnesium and a trace amount of silicon. The thickness range of the current steel plate can be produced is 0.13mm—6.00mm, and the production width range is: 580mm—1524mm.

-

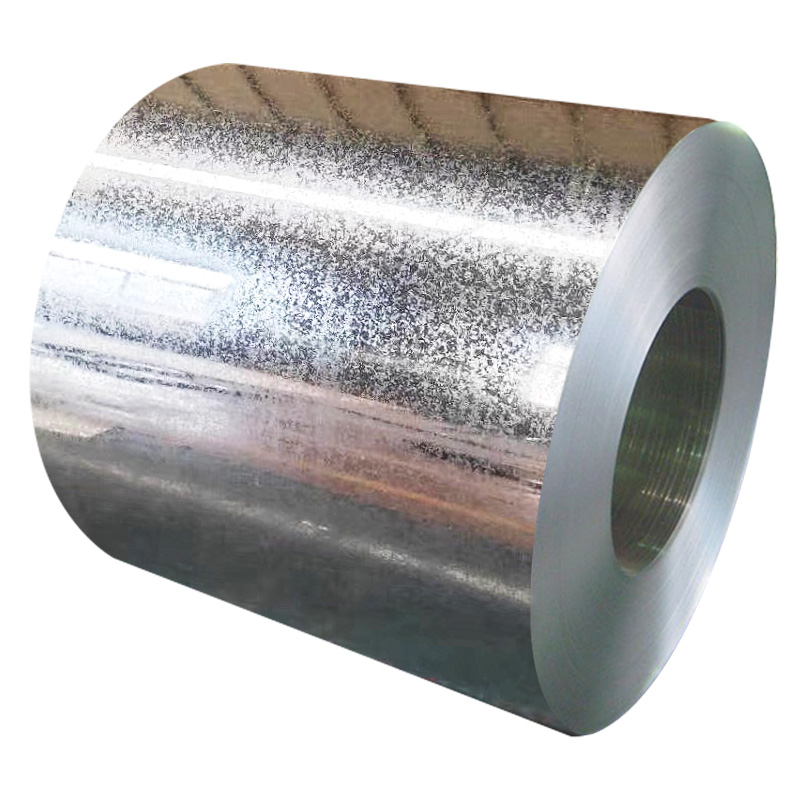

Hot dip galvanized iron coil gi coil galvanized steel DX51d, SGCC with regular spangle

Galvanized steel sheet coil features:

The surface oxidation resistance of galvanized steel coil is strong, which can strengthen the anti-corrosion penetration ability of parts.

1. Low processing cost.

2. Durable. The durability of the coating is reliable.

3. The coating has strong toughness.

4. Every part of the plated parts can be plated with zinc, which can be fully protected even in depressions, sharp corners and hidden places.

5. The galvanizing process is faster than other coating construction methods, and the time required for painting on the construction site after installation can be avoided.

6. In general, the cost of hot dip zinc is lower than that of applying other protective coatings. -

Prime Galvanized Sheet Steel Coil Roll 0.40mm, 0.5mm, 0.8mm 1.0mm

Galvanized steel sheet coil features:

The surface oxidation resistance of galvanized steel coil is strong, which can strengthen the anti-corrosion penetration ability of parts.

1. Low processing cost.

2. Durable. The durability of the coating is reliable.

3. The coating has strong toughness.

4. Every part of the plated parts can be plated with zinc, which can be fully protected even in depressions, sharp corners and hidden places.

5. The galvanizing process is faster than other coating construction methods, and the time required for painting on the construction site after installation can be avoided.

6. In general, the cost of hot dip zinc is lower than that of applying other protective coatings. -

Galvanized Steel Iron Coil Price 0.15mm 0.2mm 0.3mm Hot-dipped Galvanized

Hot dipped galvanized steel coil has strong corrosion resistance. It can prevent the surface of steel plate from corrosion and prolong its service life. Hot dip galvanized steel coil is mainly used in metal structures and facilities of various industries.

How galvanized sheet coil works on anti-corrosion: Immerse the derusted steel parts into molten zinc solution at about 500℃, so that the surface of the steel parts is attached with zinc layer, thus achieving the purpose of anti-corrosion.

Hot dip galvanizing process flow: pickling finished products, washing with water, adding plating aid solution, drying, hanging plating, cooling, medicating, cleaning, polishing and hot dip galvanizing.

-

1mm Hot-Dipped Galvanized Steel Galvanized Steel Coils Z150 Z275

Galvanized steel coil, zinc coil, bobina galvanizada. Zinc plating refers to a surface treatment technology that coats a layer of zinc on the surface of metals, alloys or other materials for aesthetics and rust prevention. The current galvanizing process mainly includes hot-dip galvanizing and electro-galvanizing, which are widely used in machinery manufacturing, electronics, precision instruments, chemicals, transportation, aerospace and other industries.

Win Road International supplies the galvanized coil production tecnique is continuous galvanizing process, that is, continuous immersion of rolled steel sheets in a galvanizing tank with molten zinc to make galvanized steel coils.

Win Road International Trading Co., Ltd

10 Years Manufacturing Experience

- jenny@winroad.net.cn

- +86 13821256534