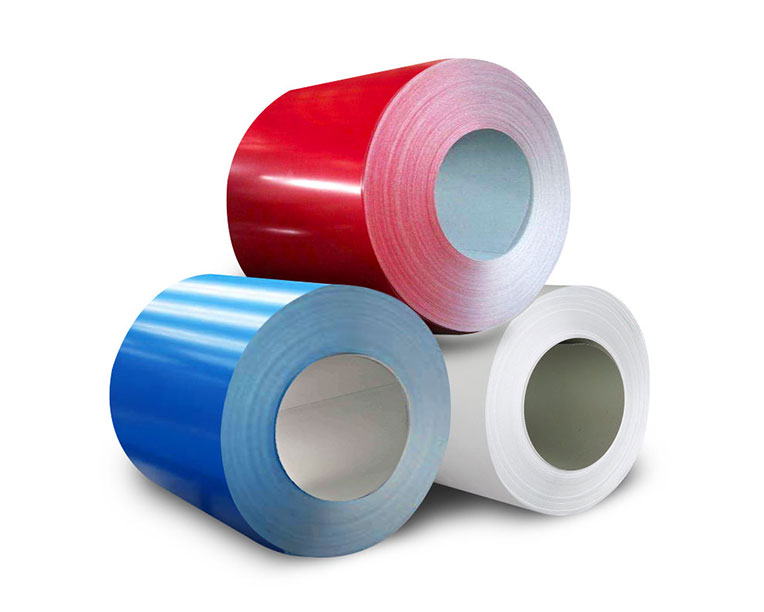

The selection of prepainted steel coil(ppgi ppgl)mainly refers to the selection of mechanical properties, substrate type (type of coating) and coating thickness, front coating performance and back coating performance. Usage, environmental corrosion, service life, durability, processing method and degree of deformation are important factors that should be considered when selecting ppgi coil and ppgl coil.

The choosing of mechanical properties, substrate type and coating weight

The mechanical properties are mainly selected according to factors such as application, processing method and degree of deformation. For example, the roof sheet of a building is usually not load-bearing, and the deformation is not complicated during processing, so DX51D is usually selected. For parts with a relatively large degree of deformation, materials with good formability such as DX52D and DX53D should be selected. For components with heavy requirements, appropriate structural steel should be selected according to the design requirements. The commonly used processing methods of color-coated sheets include shearing, bending, rolling, etc., and should be selected according to the characteristics of each processing method when ordering.

In addition, since the mechanical properties of the substrate are usually used to replace the mechanical properties of the color-coated plate in actual production, and the color-coating process may lead to changes in the mechanical properties of the substrate, attention should be paid to this. Substrate type (type of coating) and coating thickness are mainly selected based on factors such as application, environmental corrosion, service life and durability. Anti-corrosion is one of the main functions of the color-coated steel coil (ppgi ppgl coil). The type of coating and the thickness of the coating are the main factors affecting the corrosion resistance of the color-coated sheet. Since the color-coated coils for construction are usually directly exposed to the atmospheric environment, substrates such as hot-dip galvalume sheets and hot-dip galvanized sheets with good corrosion resistance and thick coating are usually selected.

The choosing of front coating performance mainly refers to the choice of coating type, coating thickness, coating color difference, coating gloss, coating hardness, coating flexibility/adhesion, coating durability and other properties.

Type of coating

Top paint coating:Commonly used topcoats are polyester, silicon-modified polyester, high-durability polyester and polyvinylidene fluoride, and there are certain differences in hardness, flexibility/adhesion, and corrosion resistance of different topcoats.

Win Road International Steel Product

Post time: May-23-2022