1. The production process of color steel plate

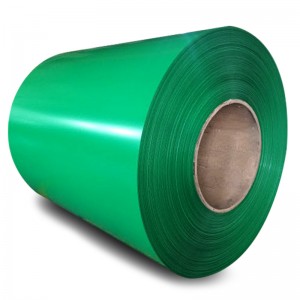

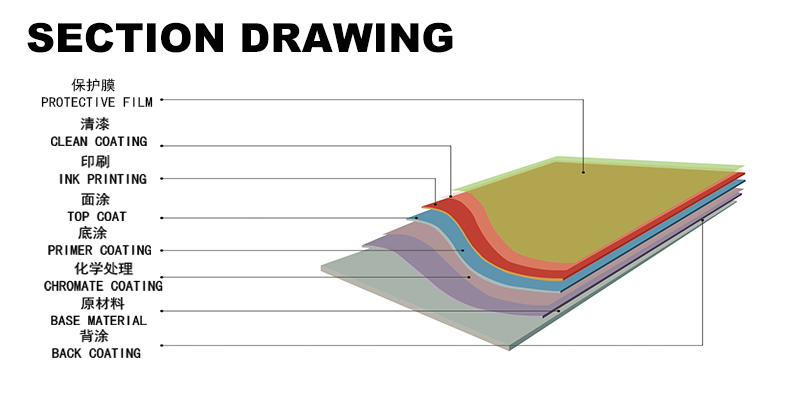

Color steel plate (also known as color plate, color coated steel plate,ppgi ppgl) is based on cold-rolled steel plate, galvanized steel plate or galvalume steel coil, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), and coating (roller coating method), a product made by baking and cooling.

The coating structure includes two coats and one bake, two coats and two bakes, etc. The maintenance-free service life can be 10-30 years depending on the ambient atmosphere.

The main production process of the common two-coating and two-baking type continuous color coating unit is: uncoiler-------stitching machine------pressing roller------tensioning machine--- -Uncoiling Looper-----Alkaline Degreasing----Cleaning----Drying-----Passivation-----Drying------Beginning Coating ------- initial coating and drying------ topcoat fine coating------ topcoat drying------ air cooling and cooling------ winding work Set ----- rewinder----- (the next roll is packed and put into storage).

Common substrates for color coated steel coil(ppgi ppgl coil)

(1) Cold rolled substrate

The color plate produced from the cold-rolled substrate has a smooth and beautiful appearance and has the processability of cold-rolled plate; however, any small scratches in the surface coating will expose the cold-rolled substrate to the air, which will quickly expose the iron to the Generates red rust. Therefore, such products can only be used for temporary isolation measures and interior materials with low requirements.

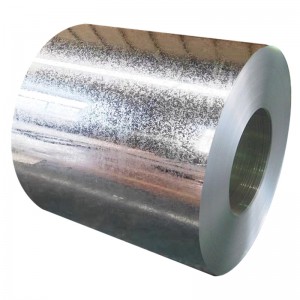

(2) Hot dip galvanized substrate

The product obtained by coating the organic coating on the hot-dip galvanized coil is the hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of the hot-dip galvanized color-coated sheet also plays the role of insulation and protection, preventing rust, and the service life is longer than that of the hot-dip galvanized sheet. The zinc content of the hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum zinc content of the hot-dip galvanized substrate for building exterior is 275g/m2.

(3) Hot-dip Al-Zn substrate

On request, hot-dip galvalume coil can also be used as color-coated substrates (55% AI-Zn and 5% AI-Zn).

(4) Electro-galvanized substrate

The electro-galvanized sheet is used as the substrate, and the product obtained by coating organic paint and baking is electro-galvanized color-coated sheet. Because the zinc layer of the electro-galvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for use. Make walls, roofs, etc. outdoors. But because of its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Top surface coated two layers of paint and a layer of color-coated on the back surface (this kind of back paint is generally not suitable for front use)

Prepainted steel coil (ppgi ppgl) is a product made of cold-rolled steel sheet, hot-dip galvanized steel sheet or galvalume steel sheets after surface degreasing, phosphating and chromate treatment, and then coated with organic paint and baked. The commonly used coatings for color coated steel plates are polyester (BHP XRW coating system, Baosteel JZ, Korea PGS, Taiwan PE), followed by silicone resin (PSS), fluorine resin (PVDF), etc. The coating structure is divided into two The coating thickness is generally 20-25μ on the surface and 8-10μ on the back. The commonly cited standards for color-coated steel sheets are American ASTM A527 (galvanized), ASTM AT92 (aluminum-zinc), Japanese JIS G3302, European EN/0142, Korea KS D3506, Baosteel Q/BQB420

Win Road International Steel Product

Post time: Jun-22-2022