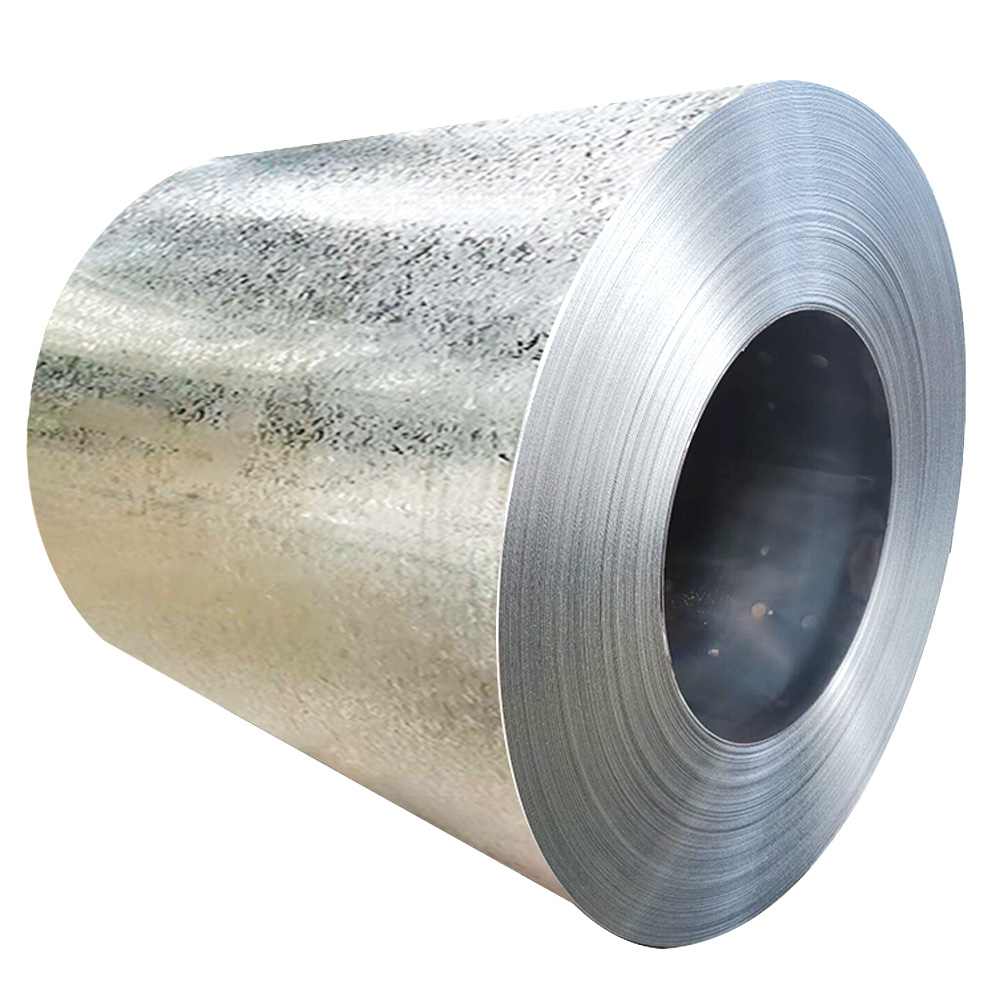

galvalume/aluzinc coil

galvanized steel coil

The surface coating of the aluminized zinc coils is composed of 55% aluminum, 43.5% zinc and a small amount of other elements. The surface of the aluminized zinc coating is a honeycomb structure under the microscopic view, and the "honeycomb" made of aluminum contains zinc. In this case, although the aluminum-zinc coating also plays the role of anode protection, on the one hand, due to the reduction of zinc content, on the other hand, the zinc material is wrapped in aluminum and is not easy to electrolyze, so the role of anode protection is greatly reduced. Therefore, once aluminum is plated The zinc plate is cut, and it will rust soon when the cut edge is basically lost and protected. Therefore, the aluminum-zinc plate should be cut as little as possible. Once cut, the edge can be protected by applying anti-rust paint or zinc-rich paint. Longer service life of plates.

The surface of the galvalume steel coils/aluzinc/zincalum presents a unique smooth, flat and gorgeous star flower, and the base color is silver-white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the aluminum-zinc plate can reach 25a, and it has good heat resistance and can be used in a high temperature environment of 315°C; the adhesion of the coating and the paint film is good, and it has good processing properties, and can be punched, cut, welded, etc.; The surface conductivity is very good.

The coating composition is composed of 55% aluminum, 43.4% zinc, and 1.6% silicon in weight ratio. The production process of galvalume steel coil is similar to that of galvanized steel coils and aluminized coilst, which is a continuous molten coating process. The galvalume/aluzinc coil with 55% aluminum-zinc alloy coating has better corrosion resistance than galvanized steel sheet of the same thickness when exposed to the same environment on both sides. The 55% aluminum-zinc alloy coated aluminum-zinc steel plate not only has good corrosion resistance, but also has the adhesion and flexibility of color-coated products.

The difference betweengalvalume/aluzinc and galvanized coils is mainly the difference in coating. The surface of galvanized sheet is evenly distributed with a layer of zinc material, which acts as an anodic protection for the base material, that is to say, the alternative corrosion protection of zinc material. In addition to the use of the base material, the base material inside can only be damaged when the zinc is completely corroded.

Post time: Jul-08-2021